7.3L Fuel Injector (2004-99)

BEFORE YOU INSTALL

Test fuel for contamination. If any is found, clean the entire fuel system prior to installing any new components

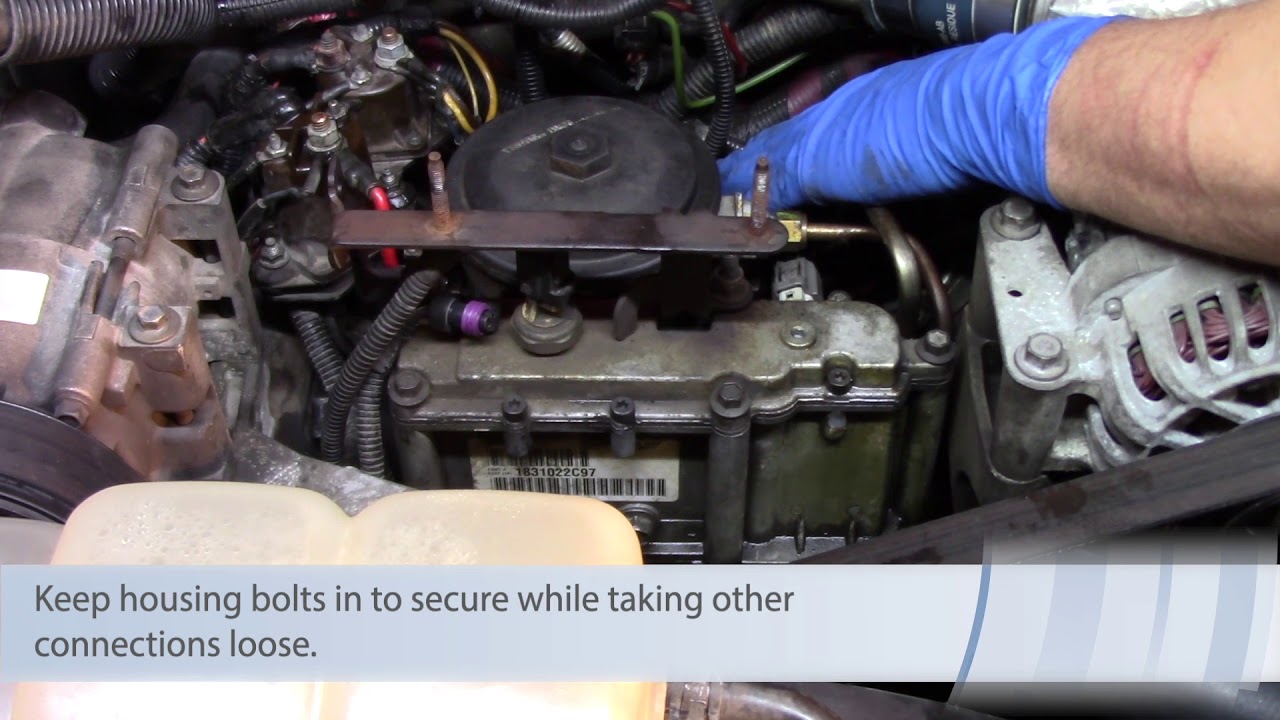

Tighten the fuel injector outboard retaining bolts and oil deflector to 12n.m (9 ft.lb torque)

Drain oil and coolant prior to injector removal just in case injector cup comes out with injector

Verify copper washer from old injector was not left in the injector cup

Oil and fuel must be removed from the cylinders prior to instillation of the injector

Verify electrical connections (valve cover, pigtail, etc.) are in good condition

Change oil, oil filter, fuel filter and prime the oil system prior to starting the engine

Related Parts

Oil Filter

Fuel Filter

Air Filter

Injector Cup

Glow Plug

Valve Cover Gasket

Features & Benefits

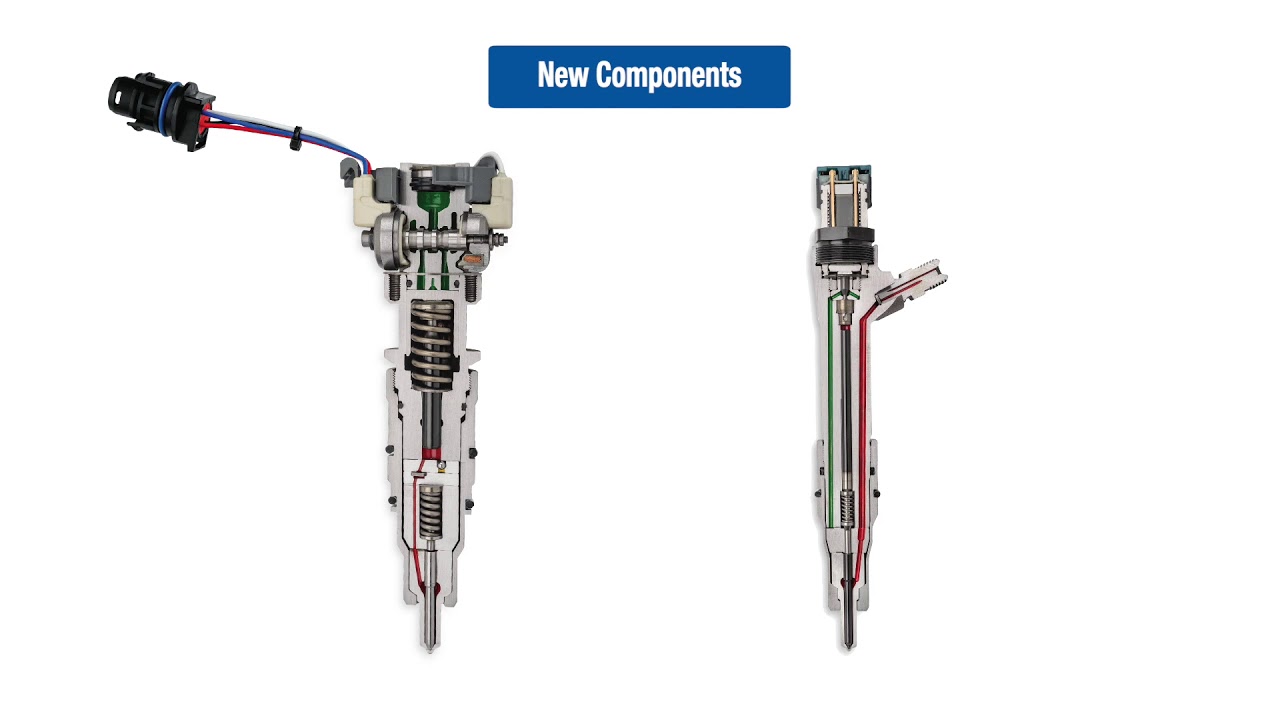

New, OE-Production Diesel Fuel Injectors:

- New OE-production fuel injector provides superior quality, emissions compliance, and fuel economy

-

Precision-manufactured with the latest engineering enhancements to match the OE injector

-

Product of OE-production design, development, engineering, and manufacturing processes, including sub-micron machining and complex assembly systems, to ensure durability

-

Undergoes extensive dynamometer, hot gas test stand, and diesel emissions testing for proper performance

-

Manufactured in the U.S.A. at IATF 16949-certified facility

Remanufactured Diesel Fuel Injectors:

- Remanufactured at our IATF 16949, ISO 9001, and ISO 14001 certified facility, where we inspect, tear down and validate, clean, reassemble, and test each part to ensure quality

-

Undergoes rigorous, multi-step cleaning process before reassembly to remove all oil and debris

-

Critical tolerances of components measured, visually inspected, and electrical tested, and either replaced or reconditioned as needed

-

Enhanced with new core components such as O-rings, springs, seals, and heat shields

-

Reassembled using precision tooling with fixturing on all stations

-

Undergoes performance testing against OEM, including fuel delivery at different RPMs and loads.

-

Laser-etched part number and date code ensures accuracy and traceability

-

Final package is sealed to provide protection from elements encountered during shipping and storage